FR4 Rigid printed circuit board | PCB | Tg 150 | Multilayer

FR4 printed circuit boards PCB (multilayer up to 40 layers)

Rigid circuit boards with that certain "extra"

"PCBs aren't just another item on your BOM."

This sentence should immediately make sense to anyone in the electronics industry. Because while most components come “off the peg” in millions of pieces, printed circuit boards are always manufactured individually for the projects. At the same time, they form the carrier and the connecting piece between all other components. The printed circuit board is what all makes electronics “play” in the first place.

We are always aware of this immensely important, central role of the printed circuit board (PCB) in terms of reliability and quality, knowing full well that the production has its individual challenges every time. Careful advice, planning and production are the three cornerstones of printed circuit board production, so that even highly complex special technologies are successful.

Industrially manufactured quality circuit boards

Leiton offers you a wide range of high-quality printed circuit board technologies and options for order processing and logistics.

With locations in Germany and China, we can produce any required volume, from express prototypes to mass production, and successfully bring your samples into series production. A large team of experts in the areas of technology, quality, logistics, production and sales is personally at your side to implement and follow up your requirements.

In addition to the usual "make to order" processes, we specialize in a wide variety of logistics agreements for optimal delivery readiness such as call-off stock, consignment stock, sea-air split delivery of series and flexible framework agreements.

Options |

|---|

| Material properties | TG130, TG150, TG170, (TG250 - no FR4), halogen-free, black FR4 |

| Material manufacturers | Panasonic, Isola, Ventec, ShengYi, ITEQ, King Board, NanYa... |

| Material thicknesses | 0,1 mm to 4,8 mm |

| Maximum PCB size | Germany 508 x 572 mm2, China 1/2-layer 530 x 606 mm2, multilayer 516 x 592 mm2, oversized PCBs on enquiry |

| Copper thicknesses | 18µm / 35µm / 55µm / 70µm / 105µm / 140µm / 210µm / 300µm / 400µm |

| Layer count | 1 to 40 layers |

| Surface finishes | HAL-lead-free, HAL, ENIG, ENEPIG, immersin tin (iSn), immersion silver, OSP, connector-gold |

| Mechanical machining | routing, milling, scoring, jump scoring, chamfering, semi-flex, depth milling, countersinking, punching |

| Drill options | Micro-vias, blind-vias, laser-vias, stacked-vias (SBU), press-fit |

| Metallizations | Edge metallization, stamp-outlines, half-opens, oblong holes, metallized slots, metallized depth milling |

| Solder mask | Lacquer, flex lacquer, coverlay. Lacquer colors: green, black, red, blue, yellow, white, special colors (all RAL colors) and matt lacquers |

| Special prints | Peelable lacquer, carbon printing, UV reflection lacquer, silk screen printing |

| Special technologies | 2mil structures, coils, frame technology, prepreg or core pressed on one side, FR4-Flex, 3M on FR4, LP numbering, special layer structures, impedance measurement, plugging, filling & tenting, copper VIA filling |

| Quality Management & Certifications | ISO 9001, ISO 14001, UL, IPC2/IPC3, IATF 16949, EMPB, VDA2, PPAP, cross-sections (x-sections), measurements, declarations of conformity, data sheets, ESD packaging and more |

| Logistics | Framework orders, consignment stock, call-off stock, sea-air split orders, express delivery from 2 working days |

Materials & properties of FR4

FR4 material is rigid and has become the standard material for printed circuit boards, compared to older materials like Pertinax, FR1 or CEM1. “FR” stands for “flame-retardant” and has a UL classification of 94V0. In the case of rigid-flex circuit boards, it forms the stable part on which components can be assembled. A popular low-cost way to make FR4 boards partially bendable is the so-called "semi-flex", where areas are simply depth-milled to achieve a certain flexibility. Common manufacturers for FR4 base materials are ISOLA, Panasonic, Kingboard, Shengyi and Nanya.

Materials of FR4 printed circuit boards

FR4 base material consists of the materials epoxy and a woven glass fiber fabric. Modern circuit board material has various fillers, which are usually required for higher temperature resistance. However, this makes the circuit board material a bit more brittle and high-TG-FR4 >150°C is therefore only of limited use for Semi-Flex. Copper is rolled-annealed onto the substrate as a conductive material.

Temperature resistance of FR4

The usual temperature resistance of FR4 is 130°C (TG130). For multilayer boards, a TG150 material is usually used as the standard, as such material expands less in the Z direction when heated and therefore allows more stable vias (PTH). High TG170 or TG180 material is used for very warm environments. TG210 materials are very rare and even higher TGs are currently not achievable with FR4, but you have to switch to polyimide or other materials. TG means “glass transition temperature”, i.e. the temperature at which the material becomes soft. The operation temperature should therefore not exceed TG minus 25°C.

| Material | Designation | Operating temperature | Material type |

|---|---|---|---|

| TG130 | Low-TG | ca. 110°C | FR4 (Epoxy-fibre-glass) |

| TG150 | Mid-TG | ca. 125°C | FR4 (filled epoxy-fibre-glass) |

| TG170 | High-TG | ca. 145°C | FR4 (filled epoxy-fibre-glass) |

| TG250 | Ultra-High-TG | ca. 220°C | Polyimide or ceramics |

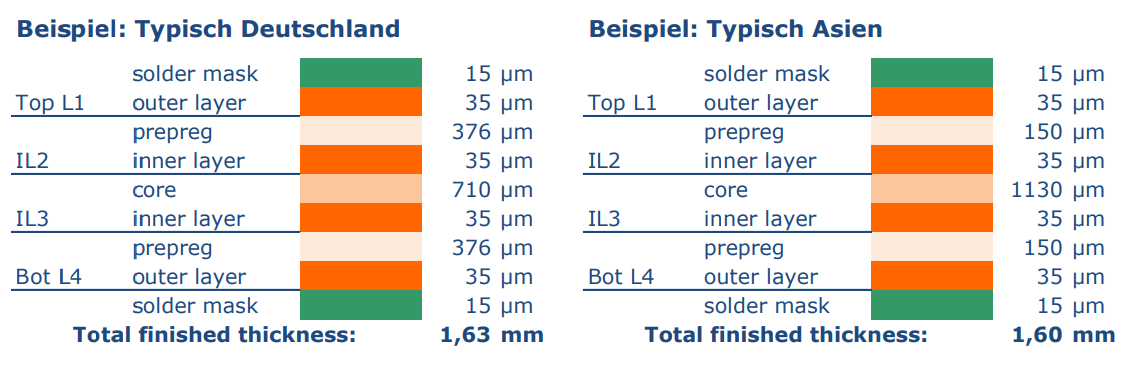

Layer structure & standard thicknesses

The standard thickness of FR4 circuit boards is 1.6mm and 1.5mm respectively. Thin rigid base materials go down to 0.1mm or 0.2mm. A thickness of 2mm is a common choice for sturdier, larger boards. Copper thicknesses are based on an American system of "Oz/ft2", i.e. "ounce per square foot". One ounce (1 oz) of copper per square foot corresponds to approximately 35µm of copper thickness. We often speak of 1 oz, 2 oz (70µm), 3 oz (105µm) when the copper thickness is meant. Starting copper before electroplating is usually around 18µm (1/2 oz). The origin in the American system explains the crooked standard values in the metric system.

The layer structures for multilayers differ significantly depending on the manufacturer and material manufacturer.

An overview of the respective standard layer structures of various thicknesses and numbers of layers can be found here as a PDF download.

Electric strength

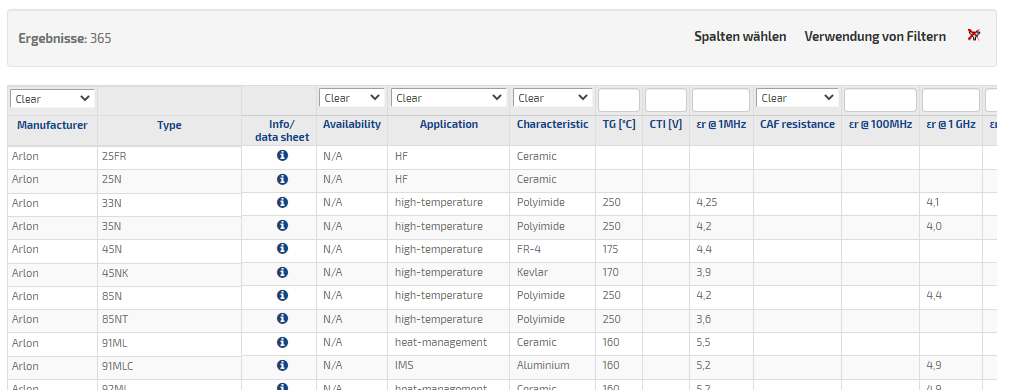

For high voltages it is important that the layers of a printed circuit board insulate sufficiently from each other. A parameter for this is the dielectric strength, which is specified in every data sheet under "Electrical Strength" in kV/mm (kilo-volts per millimeter). The IPC-TM-650 Chapter 2.5.6.2 requires at least 30kV/mm here. Common FR4 materials usually achieve 40-50kV/mm or even more.

You can find an overview of filter functions for various properties in our base material database.

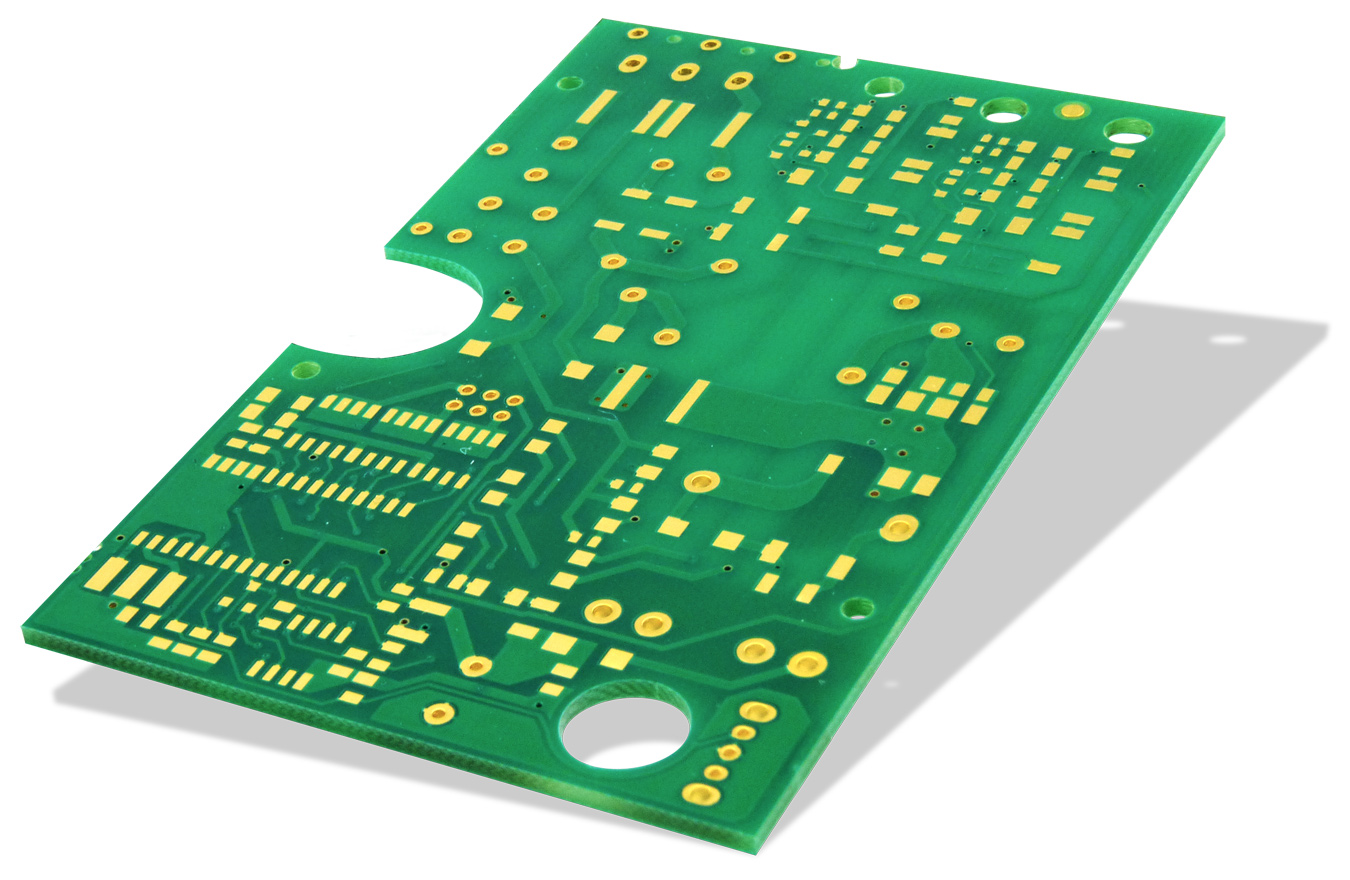

FR4 printed circuit boards (PCB)

PCB is the English abbreviation for "printed circuit board". Circuit board prototypes are already very cheap today, which is why the breadboards used in the past are not common anymore. Also, such hole grids are only suitable to a very limited extent for the assembly of SMD components, which are increasingly dominating electronics.

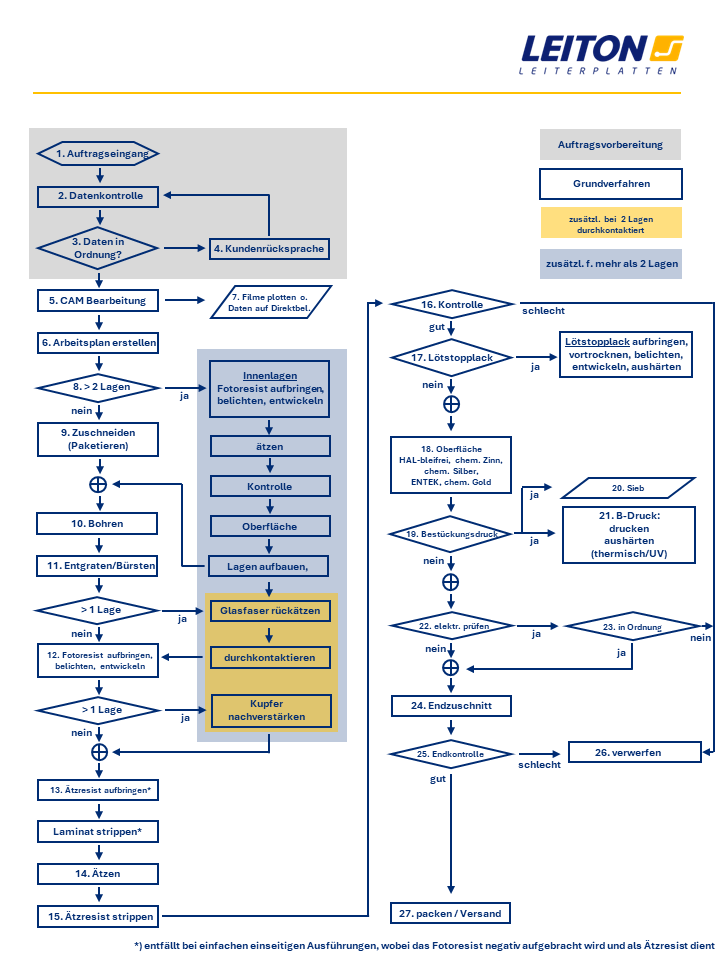

The production of our printed circuit boards

The manufacturing process of printed circuit boards is largely identical in all common productions. It can be roughly divided into mechanical, chemical and photo-sensitive processes, with industrially manufactured circuit boards moving back and forth between these process fields several times during production. A detailed circuit board production process is available for download here. The individual process steps for production are briefly explained here.

Buy cheap PCB prototypes online directly from manufacturer

At Leiton we offer cheap PCB prototypes in the online calculation or on request. A large selection of material is already available online, as well as various options regarding the number of layers, copper and total thickness, solder mask colors, special prints and finishes. Our prototypes are particularly inexpensive thanks to the “shared production” concept, with different layouts being placed on the same production blank. This saves initial costs and setup and leads to particularly low prices with the best quality.

- mechanical (M)

- chemical (C)

- photosensitive (P)

In short, the process of a 2-layer circuit board is as follows:

drilling (M) → through-hole plating (PTH/THP) (C) → laminating & exposing (P) → etching (C) → solder mask & exposing (P) → surface coating (C) → milling (M).

There are also various intermediate thermal processes, tests and cleaning steps.

since 2021

- CO2 neutral through compensation

- Circuit boards – green on the outside, also on the inside

- Expertise through active exchange

- Expertise through training and further education

- ISO 9001:2015 Quality Management

- ISO 14001:2015 Environmental Management

- UL for rigid FR4 PCBs

- UL for flexible circuit boards

- UL for aluminum IMS boards