Printed circuit board material | PCB | Buy base material | Data sheets | Database

Printed circuit boards (PCB) material & base material

(filter & compare >350 data sheets)

Here you can find a wide range of printed circuit base materials. For a detailed search use the filters or click on "learn more" for sophisticated filters. Of course you may also contact us with your requirements and we will find the right material for you. Please note that this collection has no claim on being complete, fully up to date or without errors. IT is only meant to provide a first overview for available materials which might meet your requirements.

Links to the supplier and data-sheets are accessible when clicking on each material’s info-I. If you have updates or corrections, please do not hesitate to send them to us. We will honor them with 10-Euro-PCB coupons for shopping PCBs at Leiton. Thank you.

Printed circuit base materials:

Lade Basismaterial-Datenbank...

loading content...

© Leiton GmbH - Diese Inhalte sind urheberrechtlich geschützt. Eine Vervielfältigung ist nicht gestattet.

The base material is the substrate for the assemblies and circuits of printed circuit boards (PCBs). It is delivered to the PCB manufacturer as "panel stock" and cut to the required production size on site. Numerous base materials exist with various thicknesses and coatings, as well as different electrical and mechanical properties, which influence the function of the electrical circuit.

For standard applications, the classic FR4 material is often sufficient, which is available in a high-TG variant (with improved thermo-mechanical properties). However, in the high-frequency range, different material is absolutely necessary, usually ceramic. For flexible PCBs, polyimide is used, which is also suitable for ultra-high temperature applications due to its very good temperature resistance. IMS base materials (Insulated Metal Substrates), on the other hand, are used when heat needs to be dissipated from the electronics.

The following information provides a basic overview of different PCB materials and their properties to help you make the right choice for your specific application. Basically, the base materials used for printed circuit boards can be divided into the following four most commonly used categories (other types/materials are usually found in special applications):

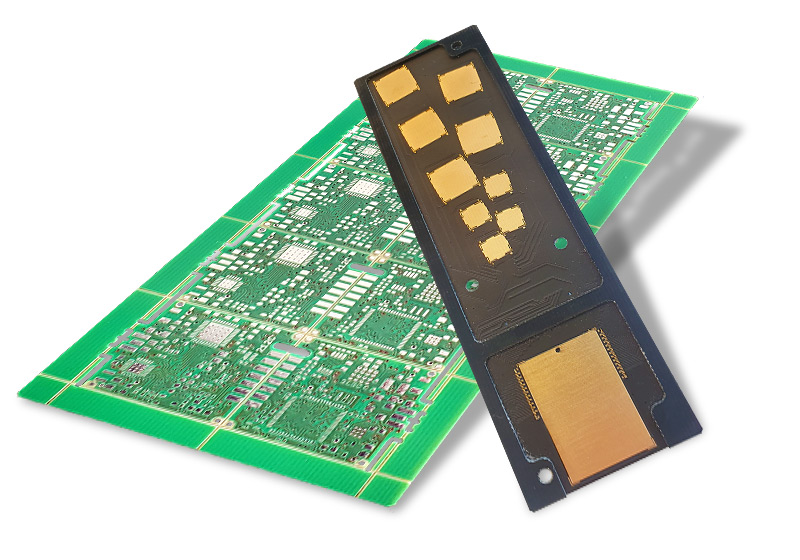

Fiberglass laminate with epoxy resin (FR4) is often used as the base material and is available as a copper-clad material (core) or as a prepreg (adhesive layer). It is a flame-retardant epoxy resin-glass fabric composite and complies with the UL94V-0 standard. It offers good adhesion for copper foil, minimal water absorption and is ideal for standard applications such as copper clad material for 1- and 2-layer PCBs or is pressed with prepreg and cores to form multilayer PCBs. High-TG and halogen-free variants are also available.

For more information on FR4 PCBs and boards, click here.

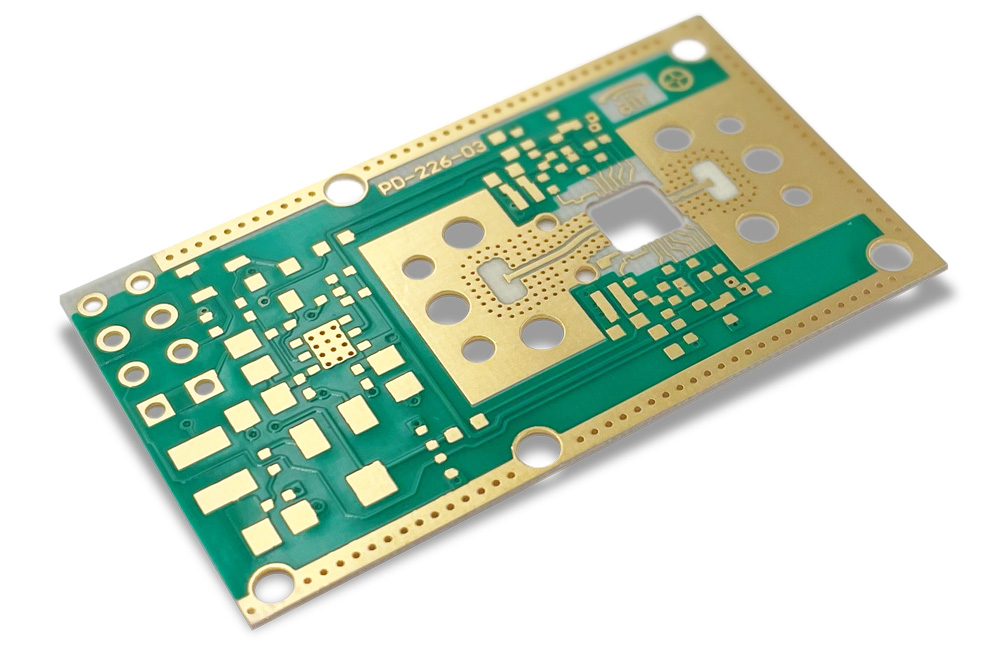

Rogers base materials are specially designed for high frequency applications. They offer excellent electrical properties and low losses at high frequencies, making them ideal for telecommunications and aerospace applications. These base materials are characterized by homogeneous dielectric constants and loss factors and are available in different types, each tailored to specific requirements.

For more information on HF circuits, click here.

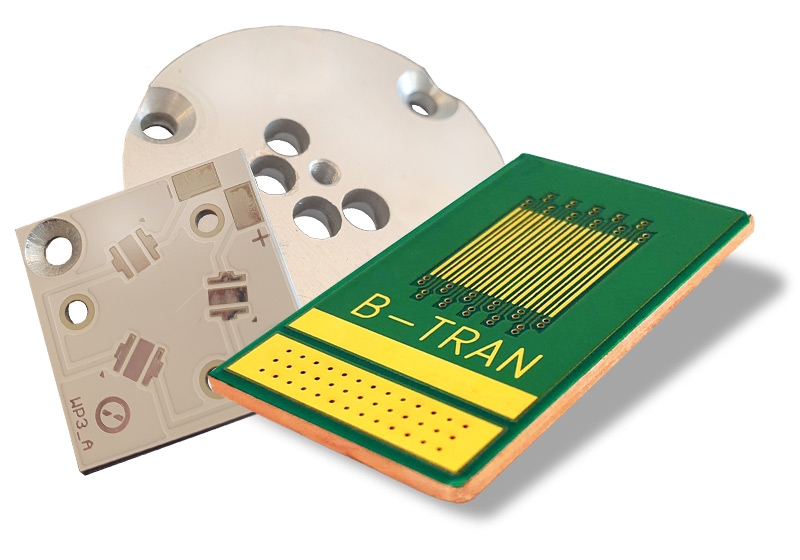

IMS (Insulated Metal Substrates) based on copper or aluminum are suitable for applications with high heat dissipation. These materials combine an insulating intermediate layer with a metallic core, typically aluminum, to ensure efficient heat dissipation from the electronics through the base material. They are often used in LED technologies and power electronics.

For more information on IMS PCBs, click here.

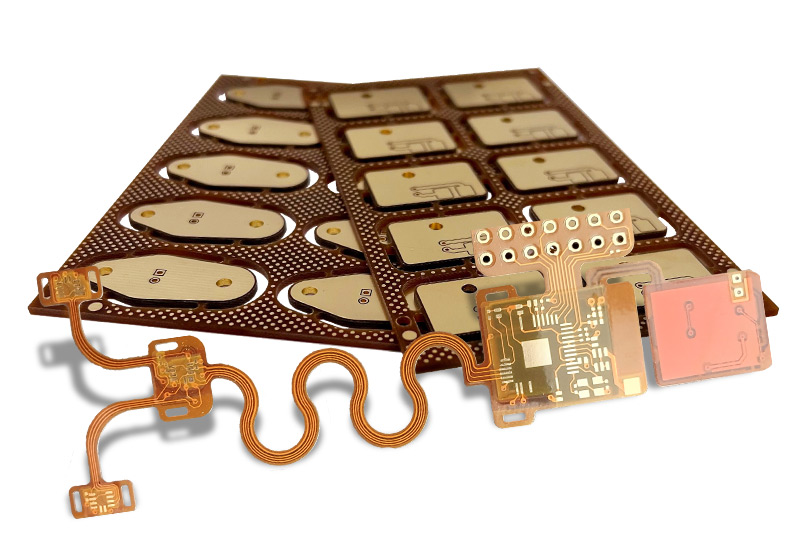

Polyimide base materials are characterized by their excellent thermo-mechanical properties and a very high glass transition temperature (TG). They are particularly suitable for applications that are exposed to extreme temperatures and mechanical stresses, such as in the aerospace and automotive industries. Polyimide materials offer high chemical resistance and excellent electrical insulation properties. However, polyimide is much more frequently used as a very thin film for flexible printed circuit boards.

For further information on this topic, please click here.